An attempt at a fairly detailed explanation of the whole thing for the regular person with high school science. Any feedback on how to make it clearer would be welcome.

1: Background. What is the problem that our transmission solves?

Newton’s first law of motion is commonly expressed in this form: unless acted upon by an outside force, an object that is at rest will tend to remain at rest, while an object in motion will remain in motion. This is also known as the law of inertia. In order to understand the usefulness of the Rolowitz Drive we need to understand the implications of this law.

Let us take the example of a car on a level road. (We will also consider the complications introduced by the need to go up and down hills, but for now let us keep it simple.) The car is stopped, the gearshift is in neutral, and the brakes are off. No force is acting upon the car, so it remains at rest. Now we wish to move the car. In order to do so we need to apply an outside force. There are two obvious ways to do this: either start the engine and put it in gear, or push the car. So as to best illustrate the process (since most of us have done this at one time or another) we will push the car, and observe what happens. First we discover that it takes a lot of pushing to get the car moving at all. Once it is moving, however, we find that as long as we are content with the speed it is moving, it does not take very much effort to keep it going. In fact if we now wish to stop the car, we have to apply almost as much effort to slowing it down as we did to speed it up. However if we stop pushing it will eventually slow down and stop.

If an object in motion tends to stay in motion, why does it slow down and stop when we stop pushing? The forces acting to slow it down are such things as friction and wind resistance. If we were in a frictionless, airless environment such as interstellar space, our vehicle, once set in motion with a push, would continue to move with no further application of force, more or less forever. If we continued to push it, it would accelerate faster and faster.

So what have we learned by this exercise? We have learned that most of the effort of moving the car is needed to get it moving and to accelerate it up to the desired speed. Once that speed has been reached the only effort required to keep it at that speed is only what is needed to overcome the friction and wind resistance that are trying to slow it down. So it might take the combined effort of three people to get the car moving and up to a certain speed, but once it has reached that speed it might take only one person to keep it going at that speed.

This principle applies to the moving of any load by any form of energy. In every case the amount of energy taken to accelerate the load to the desired speed is much greater than that required to keep it going at that speed. It applies to such things as fans and washing machines, for instance. Say we are wanting to spin-dry a load of wet clothes. What we are doing is accelerating the tub (together with the clothes and the water and also the mechanism of the electric motor itself) from rest to full speed, and then keeping it at that speed. In this case, just as with pushing the car, the amount of energy needed to get it up to speed is much greater than that needed to keep it spinning. So it is with fans, pumps, moving vehicles of all kinds, and hundreds of other uses.

What this means is that when designing a mechanism for a particular purpose, the size and power of the motor is determined by the effort it takes to get the mechanism up to speed. If all we had to do was to keep it at speed, we could get away with a much smaller motor. The irony of this is that most mechanisms spend the majority of their time running at speed, and getting there only accounts for a small amount of running time, yet this is what makes us need the large motor.

So the bottom line is that anything that reduces the amount of effort required to accelerate a load up to speed will both increase the efficiency of the mechanism and enable the use of a smaller motor, both of which are highly desirable.

How does the Rolowitz Drive help? To answer this question we need to delve into one other somewhat technical subject, which what a transmission does and why it is useful.

2. How does adding a transmission solve this problem?

A good example to illustrate the effect of a transmission is the gears on a bicycle. (These are not usually described as transmissions, but they serve the same purpose.)

Most us have ridden bicycles with gears. Imagine first a bicycle without gears. Such a bike has two drawbacks. When starting off an getting up to speed, the rider must exert a great deal of effort, and then when going fast, when little effort is required, he must pedal fast to have any effect. Both of these conditions are helped with gears. When starting off a low gear is used, enabling the rider to use relatively little effort, while requiring him to pedal faster. Once the bike is under way, a succession of higher gears enables him to pedal more slowly while still delivering power to the wheels. At speed, fairly low speed pedaling will maintain the speed because the gearing is high.

Put in more technical terms, a low gear enables a fast input with relatively low torque to move a load that it would otherwise not be able to move. Theoretically if one could achieve a low enough gear, a very small force could move almost any load if applied for long enough. However for practical purposes even though one can make a very low gear indeed by driving a very large cog with a very small one, this would not be useful, since to accelerate a load to full speed would require a series of higher and higher gears, and the resulting transmission would soon be too big and complex to work, and the friction losses in the transmission would overcome any gain.

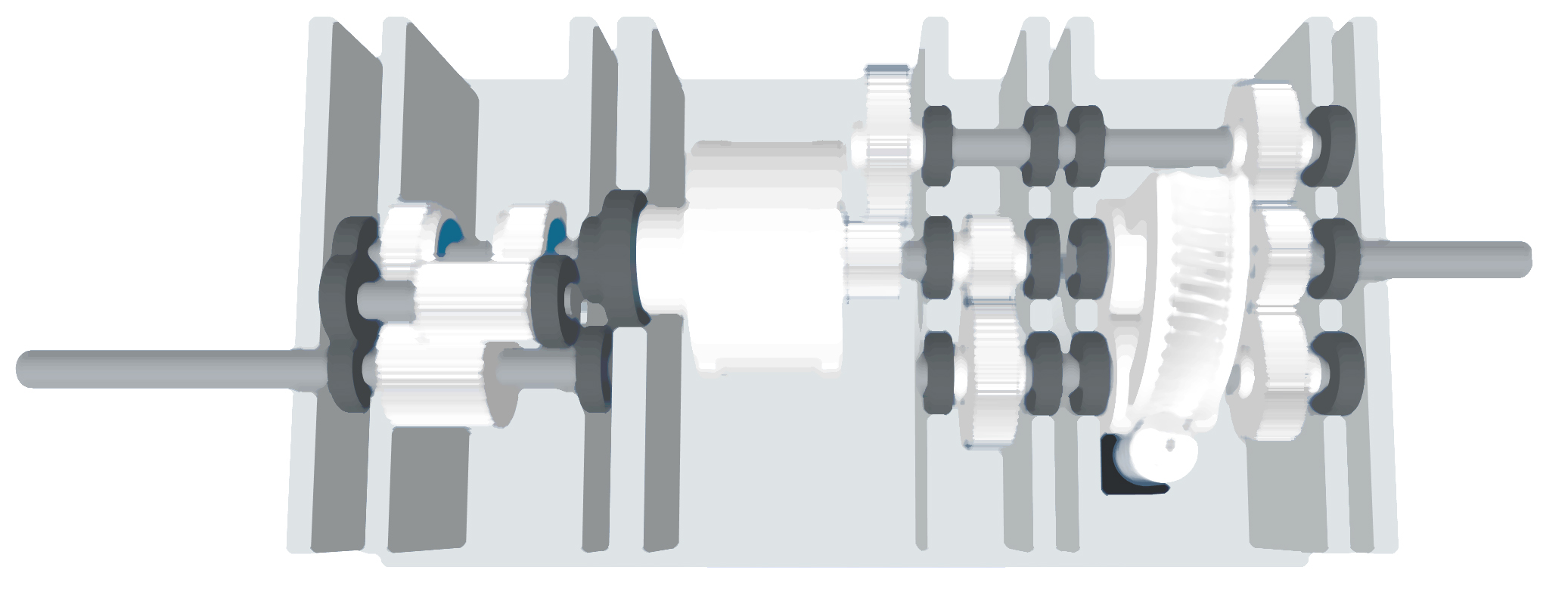

The Holy Grail of transmissions is an infinitely variable transmission. This means that instead of having discrete gears in the manner of a car or bike, it would deliver a smooth transition all the way from neutral to the highest available gear. Such a transmission would have no need of a clutch or torque converter, a major loss of efficiency in a regular transmission. There is also a class of transmission called a continuously variable transmission, the difference being that although it does deliver smooth stepless ratio change, it must be disengaged when in neutral (when no power is being transferred to the output).

3 Stationary electric motors, an almost unlimited market.

The Rolowitz Drive is a true infinitely variable transmission, in that one end of the range of settings produces a neutral gear without the use of a clutch or torque converter. This is extremely important as clutches and torque converters are not practical for use with applications such as stationary electric motors.

In addition to moving vehicles, electric motors are used to power pumps, fans, HVAC systems, all kinds of industrial processes, washing machines, refrigerators and countless other tasks. These range in size from what you might find in your household fridge to giant pumps used in water and sewage systems. All of them share one constraint. In every case they are coupled directly to the load that they are driving.

This means that we have to use a motor strong enough to move all the way from rest not just the motor itself but the entire load as well. For a motor this is like trying to push a car fully loaded with passengers and luggage, and towing a trailer!

In the case of bicycles and motor vehicles, this problem is helped by having a transmission between the engine and the load. This greatly reduces the effort needed by allowing it to first get itself up to speed, and then feed the power gradually to the wheels, going up in gear as the car travels faster. However this solution is not usable for stationary electric motors because of the complexity and cost of existing transmissions.

The Rolowitz Drive provides a low cost, low tech and small footprint solution to this problem. Now when starting our electric motor we can spin just the motor up to speed, then gradually feed in the load, increasing the gear ratio as we go, just like our bike rider starting in low gear and working his way through the gears. Only in the case of the Rolowitz Drive it is a smooth transition all the way from rest to full power, without “stepped” gears. This way even a heavy load can be driven by a much smaller motor. This applies to all kinds of motors, including modern permanent magnet motors and the like.

Because it enables the use of smaller motors for any given job, and because of its low cost and simplicity, the Rolowitz Drive will result in overall savings in cost and size when added to a system. In most cases he cost saving will more than pay for the transmission.

There are other advantages. The hard startup resulting from not having a transmission is the biggest factor in the longevity of the motor. A motor that is started once and allowed to run indefinitely would last much longer than one being started and stopped frequently. Unfortunately it is a very rare application that makes this possible. Adding the Rolowitz Drive will almost eliminate this wear and tear.

In addition when this technology is adopted on a large scale, it will have a very beneficial effect on the electrical grid. The effect of the hard starting of all of those motors is a very high current draw during startup. You may have noticed that a large air conditioning fan will cause the lights to dim, but only when starting up. At present the grid has to have enough power available to cover any likely demand. If some strange weather condition, for instance, causes a large number of air conditioners to start up at the same time, the grid must be able to handle the extra demand. This means that in practice a great deal more electricity is generated than is actually used, just in case it is needed (which is, ironically, an expensive problem. Once generated, electricity does not just disappear when not needed, it has to be dissipated. It actually costs money not to use it!) This problem would be much ameliorated by widespread use of the Rolowitz Drive.